Printed Circuit Board (PCB) manufacturing has long been the backbone of the electronics industry, enabling the creation of everything from smartphones to spacecraft. However, as the world shifts toward sustainability and smart technologies, the PCB industry is undergoing a transformative evolution. This article explores the emerging trends and innovations shaping the future of PCB manufacturing, focusing on eco-friendly practices, advanced materials, and intelligent production systems.

The Rise of Sustainable PCB Manufacturing

Traditional PCB manufacturing processes have often been associated with environmental concerns, including the use of hazardous chemicals, high energy consumption, and significant waste generation. However, the industry is now embracing sustainability as a core principle. Manufacturers are adopting greener practices, such as:

- Lead-Free and Halogen-Free Materials: The shift toward lead-free and halogen-free PCBs reduces the environmental impact and health risks associated with traditional materials. These alternatives are not only safer but also comply with global regulations like RoHS (Restriction of Hazardous Substances).

- Recycling and Waste Reduction: Companies are implementing closed-loop systems to recycle copper, solvents, and other materials used in PCB production. Advanced waste management techniques, such as chemical recovery and water recycling, are minimizing the industry’s ecological footprint.

- Renewable Energy in Production: PCB manufacturers are increasingly powering their facilities with renewable energy sources like solar and wind. This not only reduces carbon emissions but also lowers operational costs in the long run.

Advanced Materials Revolutionizing PCB Design

The demand for smaller, faster, and more efficient electronic devices is driving the development of advanced materials for PCBs. These materials are enabling new possibilities in design and functionality:

- Flexible and Stretchable PCBs: Flexible PCBs, made from materials like polyimide, are revolutionizing industries such as wearable technology and medical devices. Stretchable PCBs, which can withstand bending and twisting, are opening doors for innovative applications in robotics and IoT.

- High-Frequency Materials: With the advent of 5G and beyond, PCBs require materials that can handle higher frequencies with minimal signal loss. Materials like PTFE (polytetrafluoroethylene) and ceramic-filled laminates are becoming essential for high-speed communication devices.

- Biodegradable Substrates: Researchers are exploring biodegradable materials for PCBs, such as cellulose-based substrates. These materials break down naturally at the end of their lifecycle, addressing the growing problem of electronic waste.

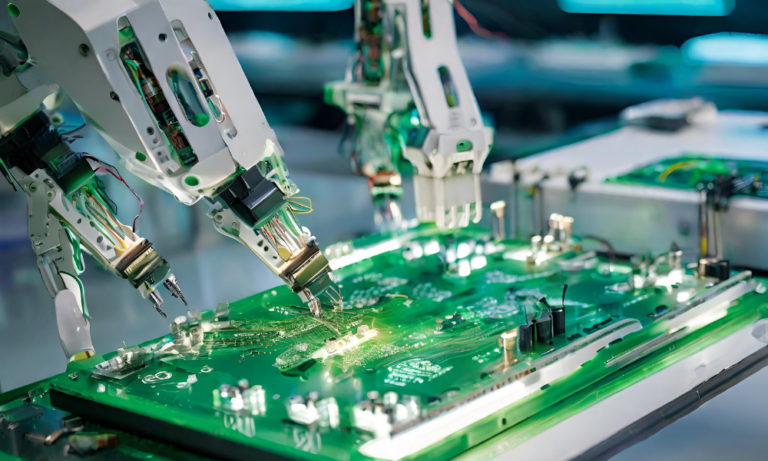

Smart Manufacturing: The Role of AI and IoT

The integration of Artificial Intelligence (AI) and the Internet of Things (IoT) is transforming PCB manufacturing into a highly efficient and intelligent process. Smart manufacturing technologies are enabling:

- Predictive Maintenance: AI-powered systems analyze data from machinery to predict potential failures before they occur. This reduces downtime and maintenance costs while improving production efficiency.

- Automated Quality Control: Machine learning algorithms are being used to inspect PCBs for defects with unparalleled accuracy. Automated optical inspection (AOI) systems can detect even the smallest imperfections, ensuring higher quality and reliability.

- Digital Twins: Digital twin technology creates virtual replicas of physical PCBs, allowing manufacturers to simulate and optimize designs before production. This reduces prototyping costs and accelerates time-to-market.

- IoT-Enabled Supply Chains: IoT devices are being used to monitor and manage the supply chain in real-time. From tracking raw materials to optimizing inventory levels, IoT is enhancing transparency and efficiency across the entire production process.

The Human Element: Upskilling the Workforce

While technology is driving innovation, the human element remains crucial in PCB manufacturing. As the industry adopts advanced technologies, there is a growing need for skilled professionals who can operate and maintain these systems. Companies are investing in upskilling programs to train their workforce in areas like AI, IoT, and sustainable manufacturing practices. This not only ensures a smooth transition to smart manufacturing but also creates new career opportunities in the industry.

A New Era for PCB Manufacturing

The future of PCB manufacturing is bright, driven by a commitment to sustainability, the adoption of advanced materials, and the integration of smart technologies. As the industry continues to evolve, it is poised to meet the demands of a rapidly changing world while minimizing its environmental impact. By embracing these innovations, PCB manufacturers are not only enhancing their competitiveness but also contributing to a more sustainable and technologically advanced future. The journey toward smarter, greener, and more efficient PCB production is just beginning, and the possibilities are endless.